Zhejiang Youji Machinery Technology Co.,Ltd >> Product >> Valve fittings >> Pneumatic Actuator >> ZT

Zhejiang Youji Machinery Technology Co.,Ltd >> Product >> Valve fittings >> Pneumatic Actuator >> ZT

ZT

Message If you want any further detail data and drawing,please contact us.

| Series : | Pneumatic Actuator |

| Name : | ZT |

| Model : | ZT series |

| PDF-DOWNLOAD : | |

| Click : | 394 |

|

Production introduction:

|

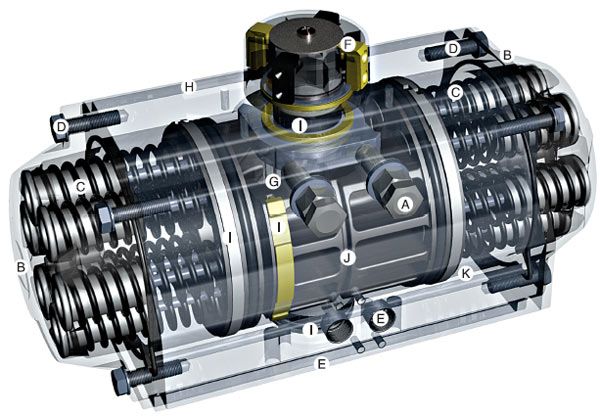

| A | Two bolts out of cylinder do ±5°adjusting to keep the actuator on/off position with the whole open position and whole closed position. |

| B | The end covers use high pressure cast Aluminum the surface platedcorridor protection one piece body design. All the single action anddouble action actuator used the same cylinder and cover we can changethe action ways by adding/removing springs. |

| C | Combined preload spring design submit to any setting occasion and it will be safer when you remove it. |

| D | Stainless steel material be used in all the fasteners. |

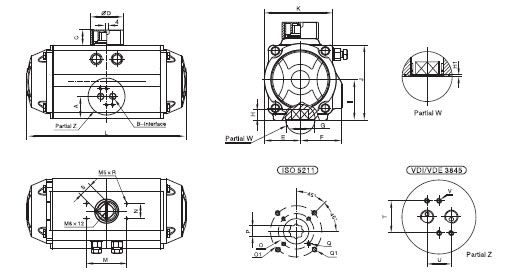

| E | The connect dimension designed according to international standard: ISO5211-DIN3337 and DI/DE3845,the air supply connect design as per NAMUR standard. |

| F | There is a function position indicator with NAMUR standard groovein the shaft end. It’s convenience to setting the signal switch box. Thepositional position responsive switch and the other fittings are suitablewith VDE3845 standard. |

| G | Drive shaft: plated nickel, so all the inner and outside can proof-co- rrosion, the shaft also can anti breakout and the leading bearing int- egration design ,so it should be more safer, and cater-corner square each installation, the flexibility is good. |

| H | New type Aluminum alloy cylinder, delicate manufacturing, the inner wall and the surface have been hard coat anodize treated,low coefficients of friction long service life. |

| I | Combining piston ring on the piston, the abrasion proof plastic behind the piston, the abrasion proof ring of driving shaft has an extremely low coefficient of friction. |

| J | These two gear symmetry fixed, to keep the out put torque not change. make the giving power balance ,with a greater accuracy. |

| K | Insider air channel ,it needn’t use to connect the open pip line. |

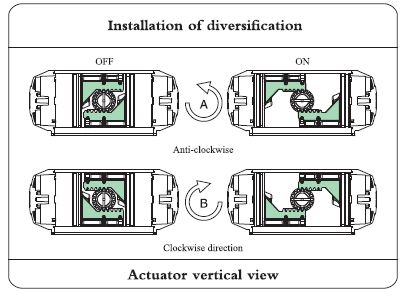

| Operation principle and rotation direction | ||

| Standard rotation direction :clockwise to closed ,and inverted hour to open. | ||

| Operation principle of double action standard vertical view.(standard rotation) | ||

|

||

| Operation principle of single action standard vertical view:(standard rotation) | ||

|

||

| The used lectotype of double action: | ||

| Please confirm the safety factor before you install the pneumatic actuators. And the safety factor should be changed if the medium,service temperature ,pressure ,friction force between spool and seat insert and otherwise data changed. |

||

| Known: the torque of butterfly valve is 150Nm,medium:water,temperature is normally ;and the supply air pressureis 5 bar ,safe factor is 20% The safety toque is :150+20%=180Nm,please reference the double action actuator torque list on page 08,you may find the supply pressure is 5 bar , and then find the data about 180Nm in this row ,see 215Nm the mode number :ZT115 should be used in this mode. | ||

| The used lectotype of single action: | ||

| Please first considering the torque under the air supply action and the torque under the extension. | ||

| Known: ball valve torque is 200Nm, medium: steam ,service temperature is :160℃,the gas source is 5.5bar ,and the safe factor is 25%; the safety torque : 200+25%=250Nm. Reference the single action actuator torque list on page07 : you can find the row of source pressure 5.5bar , then find the torque this line (open and finish ) ,and rightwardsfind the torque of the spring start and finish. You may find the actuator mode NO. ZT 160 is suitable. and the spring Qty is 11, please find the following data: The gas source pressure 0°=377Nm GQS pressure 90°=259Nm Spring travel 0°=247Nm Spring travel 90°=365NmPS : the torque you find is approximated the safety factor. |

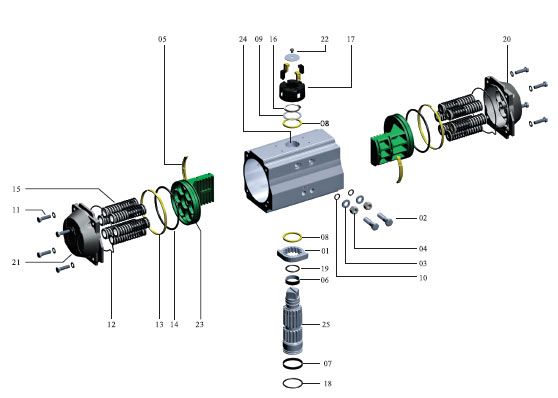

| Parts No | Single quantity | Parts Name | Standard Materials | Anti-corrosion Level | Backup material |

| 01 | 1 | Adjusting cam | stainless steel | ||

| 02 | 2 | Adjusting bolt | stainless steel | ||

| 03 | 2 | Gasket | stainless steel | ||

| 04 | 2 | Nut | stainless steel | ||

| 05 | 2 | Direction of bashing (back of piston) | composite material | ||

| 06 | 1 | Bearing wear ring (top) | nylon 46 | ||

| 07 | 1 | Bearing wear ring (end) | nylon 46 | ||

| 08 | 2 | Trusting gasket (drive axes) | composite material | ||

| 09 | 1 | Trusting rings(drive axes) | stainless steel | ||

| 10 | 2 | O-ring (adjusting bolt ) | NBR | Fluorine or silastic | |

| 11 | 8 | End cover bolt (end cover) | stainless steel | ||

| 12 | 2 | o-rings (end covers ) | NBR | Fluorine or silastic | |

| 13 | 2 | abrasion proof composition ring(piston) | composite material | ||

| 14 | 2 | O-rings (piston) | NBR | Fluorine or silastic | |

| 15 | 5-12 | Spring | alloy spring steel | Epoxy resin coat | |

| 16 | 2 | Flexible ring | stainless steel | ||

| 17 | 2 | Position indicator | composite material | ||

| 18 | 2 | O-rings (end ) | NBR | Fluorine or silastic | |

| 19 | 2 | O-rings(top) | NBR | Fluorine or silastic | |

| 20 | 2 | end cover | casting aluminum alloy | Polyester coating | |

| 21 | 2 | end cover | casting aluminum alloy | Polyester coating | |

| 22 | 1 | Screw | stainless steel | ||

| 23 | 2 | Piston | casting aluminum alloy | Anodze oxidation | |

| 24 | 1 | Cylinder | Extrusion aluminiumalloy | Hard coat anodze | |

| 25 | 1 | driving axes | carbon | Nickel plated | stainless steel |

|

ZT050 | ZT063 | ZT075 | ZT088 | ZT100 | ZT125 | ZT160 | ZT200 | ||

| A-120° | 159.5 | 179.5 | 240 | 281 | 306 | 395 | 500 | 618 | ||

| A-180° | 197 | 221.5 | 298.5 | 348 | 381.5 | 496 | 626 | - | ||

| J | 68 | 85 | 102 | 115 | 127 | 157 | 196 | 245 | ||

| K | 59 | 72 | 84.5 | 97.5 | 111 | 136 | 169 | 213 | ||

| V | M5*8 | M5*8 | M5*8 | M5*8 | M5*8 | M5*8 | M5*8 | M5*8 | ||

| R | 4 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | ||

| M | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 130 | ||

| N | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | ||

| G | 30 | 35 | 35 | 55 | 55 | 70 | 85 | 100 | ||

| H | 12 | 16 | 16 | 19 | 19 | 24 | 29 | 38 | ||

| E | 29 | 36 | 42.5 | 49.5 | 56 | 69.5 | 88 | 110 | ||

| F | 41.5 | 47 | 52 | 56.8 | 67 | 82 | 99 | 112 | ||

| S | 11 | 11 | 19 | 19 | 19 | 27 | 27 | 42 | ||

| A | 26.5 | 30 | 30.5 | 32.5 | 37.5 | 45 | 52 | 62 | ||

| C | 20 | 20 | 20 | 20 | 20 | 30 | 30 | 50 | ||

| O | 42 | 50 | 50 | 70 | 70 | 102 | 125 | 140 | ||

| 01 | - | - | - | - | - | - | - | - | ||

| T | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | ||

| U | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 | ||

| Q | M5 | M6 | M6 | M8 | M8 | M10 | M12 | M16 | ||

| Q1 | - | - | - | - | - | - | - | - | ||

| T-ISO228 | 1/8’ | 1/8’ | 1/8’ | 18/’ | 1/4’ | 1/4’ | 1/4’ | 1/4‘ | ||

| ISO5211 | F04 | F05 | F04 | F07 | F07 | F10 | F12 | D14 | ||

| P | 11 | 11 | 11 | 17 | 17 | 22 | 27 | 36 | ||

| H1 | 0.5 | 0.5 | 0.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | ||

| I | 34.5 | 42.5 | 51 | 57.5 | 63.5 | 78.5 | 98 | 122 | ||

| D | 40 | 40 | 40 | 40 | 40 | 56/65 | 65 | 80/155 |

| Note: For ISO installation options at the bottom of flange and the Quartet’s size, see the travel of 90 ° |

| Model Type | ZT050D | ZT063D | ZT075D | ZT088D | ZT100D | ZT125D | ZT160D | AT200D |

| Bore Φ(mm) | 50 50 | 63 63 | 75 75 | 85 85 | 100 100 | 125 125 | 160 160 | 200 200 |

| Stroke adjustment /1°Needed to turn a few | 1/6 1/6 | 1/6 1/6 | 1/6 1/6 | 1/5 1/5 | 1/5 1/5 | 1/4 1/4 | 1/4 1/4 | 1/4 1/4 |

| Open to the cylinder volume (L) | 0.11 0.17 | 0.2 0.29 | 0.39 0.56 | 0.63 0.92 | 0.9 1.3 | 1.9 2.8 | 3.9 5.7 | 7.4 - |

| Clearance to the cylinder volume (L) | 0.18 0.27 | 0.32 0.47 | 0.61 0.88 | 0.97 1.4 | 1.4 2 | 2.9 4.2 | 6.2 8.8 | 11.8 - |

| Opening Time S(Sec.) | 0.26 0.31 | 0.33 0.39 | 0.39 0.47 | 0.52 0.63 | 0.65 0.79 | 1.17 1.41 | 1.95 2.36 | 3.51 - |

| Closing time S(Sec.) | 0.33 0.39 | 0.39 0.47 | 0.52 0.63 | 0.65 0.79 | 0.91 1.10 | 1.56 1.88 | 2.34 2.83 | 4.55- |

| Approximate weight (Kg) | 1.2 1.5 | 2 2.5 | 3.4 4.4 | 4.6 6 | 6.6 8.1 | 12.3 15.4 | 24.6 29.5 | 44 - |

| (A) The action sec . of pneumatic actuator was Resulted from the follow conditions:(1) service temperature (2)120°and 180°travel(3)The bore size of solenoid valve is 4mm. and the negotiability is Qn400L/min (4)pipe inner size is 8mm.(5)neutrality tidy air. (6) gas source pressure is 5.5bar .(7)All the actions were tested without connected actuator. Note :The actuator seconds would be changed if Any double items above changed. ★Actuator 120°travel and 180°travel can just be double actions. ★The travels should be changed if customers request except 120°and 180°travel. |