- Valve testing equipment

- Pump-valve

- Gate valve

- Globe valve

- Check valve

- Butterfly valve

- Pump

- Ball valve

- Valve fittings

- Pneumatic Actuator

- Electric Actuator

Zhejiang Youji Machinery Technology Co.,Ltd >> Product >> Valve testing equipment >> JLD butterfly valve test bench

Zhejiang Youji Machinery Technology Co.,Ltd >> Product >> Valve testing equipment >> JLD butterfly valve test bench

JLD butterfly valve test bench

Message If you want any further detail data and drawing,please contact us.

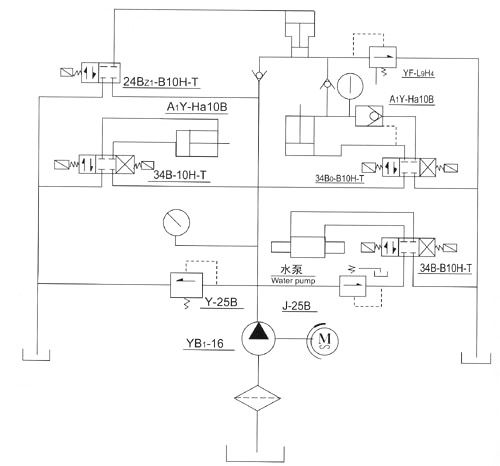

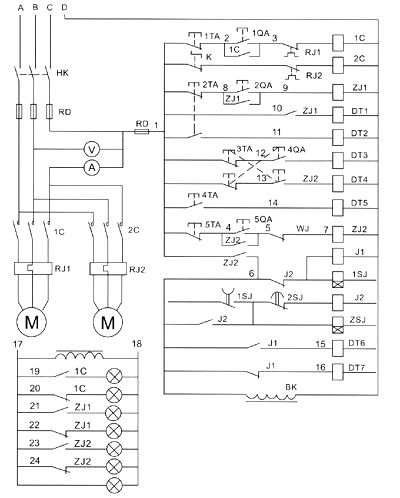

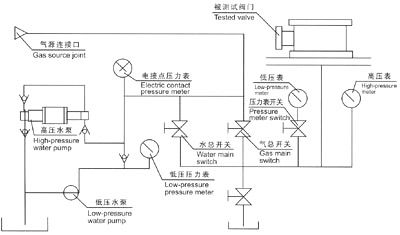

1.JLD hydraulic butterfly valve test bench works and how to use

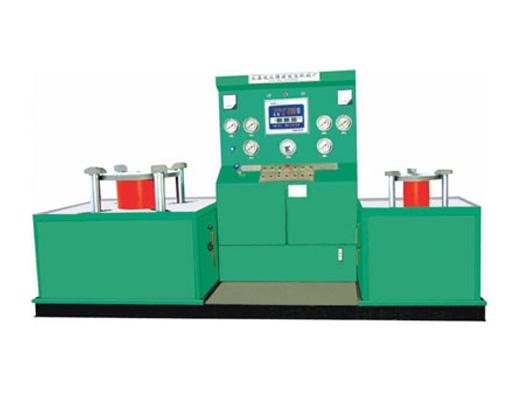

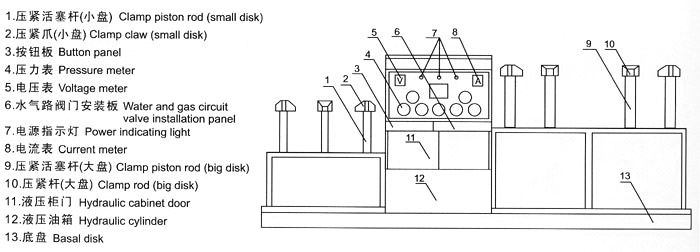

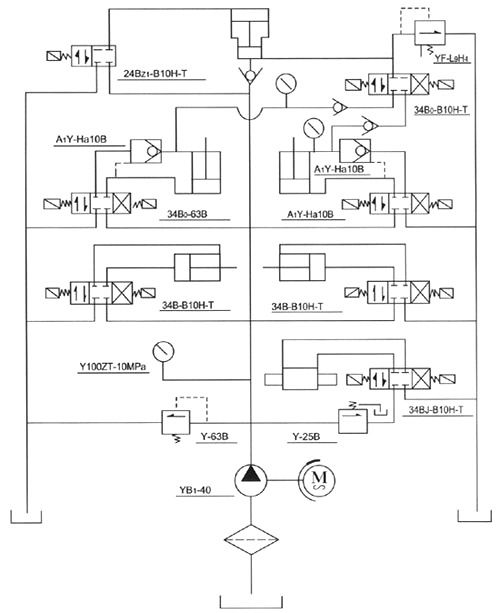

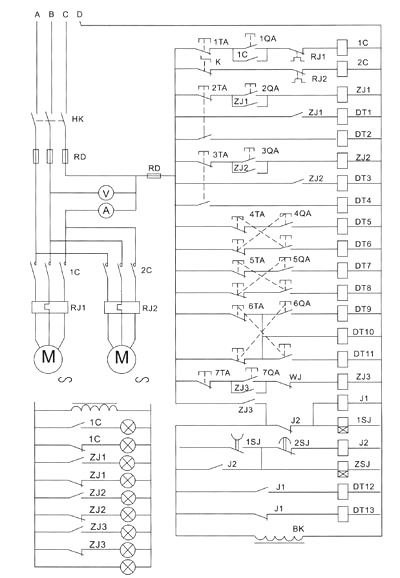

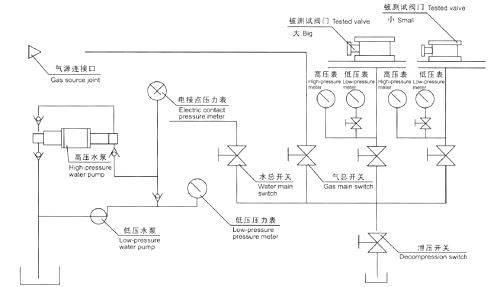

JLD butterfly valve test bench is a special type butterfly valve butterfly valve performance tests applied to the detection equipment. The machine set of mechanical, electrical, fluid and hydraulic pressure device for circulating water system in one, table with clamping claws clamping cylinder direct-drive valve to achieve the test, so that the claw force uniform, clamping reliable, clip bear claw radial mobility features with cylinders, connecting rod, achieving simultaneous radial movement of claws to ensure the size of the diameter of the butterfly valves of different tests, when sealed, if the butterfly valve with a clamping flange, not the butterfly orchid from a direct extension of hydraulic clamps are clamped butterfly valve plane can be tested. The aircraft can be directly whether the leaking valve cavity bubbles or risk, such as the test intensity blind stamped on the plate can be sealed in the machine can do the valve electric device on the torque and 90-degree opening and closing test. The machine comes with hydraulic pressure for the pumps, storage media can be recycled to use. The use of clean water must be added anti-rust agent, so as not to rust and impact of post-test valve hydraulic pressure device for the use of normal function.

Usage:

[1], With 30 # -40 # 20 # hydraulic oil or machine oil into the hydraulic system of the fuel tank, the fuel indicator can not be less than the lower limit of oil.

[2], Connected to power, jog pump start button, and check the motor rotation direction is correct (clockwise).

[3], Transferred to the hydraulic system pressure 5.0MPa, which can work properly.

[4], Working procedures:

(1) The largest moving clamps retreated position; (2) Will be on the bench test valve sealing plate center; (3) Moving into a small claw clip to the desired location the measured valve.

(4)Dynamic clamping claws clamping tested Butterfly Valve (flange, or flat); (5) Pressurized to the required twisting pressure (clamping cylinder pressure required to control the table) (attached to the computer). Booster button to jog several times, each time interval of three seconds, if so, (referring to the first press does not meet the required pressure). The maximum pressure of 32MPa; (6)Hydraulic or pneumatic pilot valve being tested; (7) Testing has been completed, open turn on the water or air switch, vent off the pressure can be; (8) Respectively in accordance with their relaxed button, will be measuring valve removed.

2. Using and requirements

(1), equipment installation: the school placement level or your equipment fixed with concrete footing bolts.

(2), choose N32 - 46 # regular hydraulic oil, N32-46 # anti-wear hydraulic oil, or 20 - 30 # machine oil into the fuel tank, fuel can not be less than the lower limit of the oil level gauge.

(3), connect the power, press the start button pump, check the motor rotation direction is correct (clockwise direction) for 5 - 10 minutes no-load running, adjust oil pump pressure in the 5 0MPa test-machine, all kinds of movements, check the tube whether the leak path and found that negative phenomena should immediately stop excluded.

(4), test medium: water is convenient and does not pollute the environment, etc., which are widely used, to ensure no erosion of the valves were tested and in the media, the requirements of the testing machine. In the tank, add rust inhibitor, or used for testing the oil medium.

(5), test valve, the first valves were tested under the test pressure, insisted that "the pressure needed to compress cylinder control table" in the hydraulic clamping system pressure value, to boost pressure regulation, the value of super-boost pressure is strictly prohibited high, and prevent damage to test the valve deformation.

(6), hydraulic pump for the pressure to work before conditioning and being a good electric contact pressure gauge pressure pilot valves the same, and then to work.

Cast iron valve not use the hammer, the valve in the experiment, the operator should pay attention to safety, proper use, with particular attention when the test medium pressure cast iron valves too damaged, valve testing is completed, the valve should be ranked after exhausting internal pressure can be relaxed axial press.

(7), pressure gauge testing devices must be approved by the local department accreditation of its measurement certificate shall be valid, the pressure gauge of the range can not be less than the test pressure 1.5 times the precision of not less than 1.5.

(8)

[1]. Test bench face should be kept dry; fight, clean and test the valve by sealing plate flange and not allowed to have their fixed debris, always check the O-ring damage.

[2] Test bed activities of the various components of office, should always refuel and maintain clean lubrication to use.

[3]. Hydraulic oil should be regularly inspected, the replacement of new equipment put into use, so that both the cleaning tank 3 months, replaced with new oil, after cleaning and replacing every other year, once the oil level gauge oil can not be less than the lower limit of the fuel tank the temperature inside the oil should not exceed 55 ~ C.

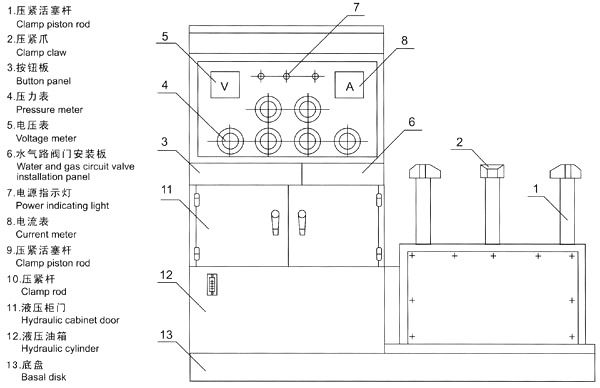

JLD hydraulic valve test bench (set type) Appearance Schematic

300 type clamping cylinder pressure contrast table

| Nominal diameter DN | Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 3 | 80 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.5 | 4.5 | 7.0 |

| 4 | 100 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 3.0 | 4.0 | 4.0 | 6.0 | 6.0 | 9.0 |

| 6 | 150 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 | 7.5 | 7.0 | 10.5 | 11.0 | 16.0 |

| 8 | 200 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 6.0 | 5.0 | 7.5 | 7.5 | 11.5 | 12.0 | 18.0 | ||

| 10 | 250 | 3.0 | 3.0 | 3.0 | 4.0 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 17.0 | 25.5 | ||

| 12 | 300 | 3.0 | 4.0 | 4.0 | 6.0 | 6.0 | 9.0 | 9.5 | 14.5 | 15.0 | 22.5 | ||||

400 type clamping cylinder pressure contrast table

| Nominal diameter DN | Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 6 | 150 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 4.5 | 5.0 | 7.5 | ||

| 8 | 200 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 5.0 | 5.5 | 8.0 | 8.5 | 12.5 | ||

| 10 | 250 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 5.0 | 5.0 | 7.5 | 8.0 | 12.0 | 12.5 | 18.5 | ||

| 12 | 300 | 3.0 | 3.0 | 3.0 | 4.0 | 4.5 | 6.0 | 7.0 | 10.5 | 11.0 | 16.5 | 17.0 | 25.5 | ||

| 14 | 350 | 3.0 | 3.0 | 4.0 | 5.5 | 6.0 | 9.0 | 9.0 | 13.5 | 14.5 | 21.5 | ||||

| 16 | 400 | 3.0 | 4.0 | 4.5 | 7.0 | 7.5 | 11.0 | 11.5 | 17.5 | 18.5 | 27.5 | ||||

500 type clamping cylinder pressure contrast table

| Nominal diameter DN | Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 10 | 250 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | ||

| 12 | 300 | 3.0 | 3.0 | 3.0 | 3.5 | 3.5 | 5.0 | 5.0 | 7.5 | 8.5 | 12.5 | 13.0 | 19.5 | ||

| 14 | 350 | 3.0 | 3.0 | 3.0 | 4.0 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 17.5 | 26.5 | ||

| 16 | 400 | 3.0 | 3.0 | 4.0 | 5.0 | 5.5 | 8.5 | 9.0 | 13.5 | 14.5 | 21.5 | ||||

| 18 | 450 | 3.0 | 4.0 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 18.0 | 27.0 | ||||

| 20 | 500 | 4.0 | 5.0 | 5.5 | 8.0 | 8.5 | 12.5 | 13.5 | 20.0 | ||||||

600 type clamping cylinder pressure contrast table

| Nominal diameter DN |

Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 12 | 300 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.5 | 5.0 | 5.5 | 8.5 | 9.0 | 13.5 | ||

| 14 | 350 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 5.0 | 7.0 | 7.5 | 11.0 | 12.0 | 18.0 | ||

| 16 | 400 | 3.0 | 3.0 | 3.0 | 3.5 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | 15.0 | 22.5 | ||

| 18 | 450 | 3.0 | 3.0 | 3.0 | 4.0 | 4.5 | 7.0 | 7.5 | 11.0 | 12.0 | 18.0 | ||||

| 20 | 500 | 3.0 | 4.0 | 4.0 | 5.0 | 5.5 | 8.0 | 8.5 | 13.0 | 14.0 | 21.0 | ||||

| 24 | 600 | 3.0 | 5.0 | 5.0 | 7.5 | 8.0 | 12.0 | 13.0 | 19.0 | 20.0 | 30.0 | ||||

800 type clamping cylinder pressure contrast table

| Nominal diameter DN |

Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 16 | 400 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.5 | 5.0 | 7.0 | 7.5 | 11.0 | 11.5 | 17.0 | ||

| 18 | 450 | 3.0 | 3.0 | 3.0 | 3.5 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | 14.5 | 21.5 | ||

| 20 | 500 | 3.0 | 3.0 | 3.0 | 4.0 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | ||||

| 24 | 600 | 3.0 | 4.0 | 4.0 | 6.0 | 6.5 | 9.5 | 10.0 | 15.0 | 15.5 | 23.0 | ||||

| 28 | 700 | 4.0 | 5.0 | 5.5 | 8.0 | 8.5 | 12.5 | 13.0 | 19.5 | ||||||

| 32 | 800 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 17.0 | 25.5 | ||||||

1000 type clamping cylinder pressure contrast table

| Nominal diameter DN |

Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 20 | 500 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 4.0 | 4.5 | 7.0 | 7.0 | 11.0 | 12.0 | 18.0 | ||

| 24 | 600 | 3.0 | 3.0 | 3.0 | 3.5 | 4.0 | 6.0 | 6.5 | 10.0 | 10.5 | 15.5 | 16.5 | 24.5 | ||

| 28 | 700 | 3.0 | 3.0 | 4.0 | 5.0 | 5.5 | 8.5 | 9.0 | 13.5 | 14.0 | 21.0 | ||||

| 32 | 800 | 3.0 | 4.0 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 18.0 | 27.0 | ||||

| 36 | 900 | 4.0 | 5.0 | 5.5 | 8.5 | 9.0 | 13.5 | 15.5 | 21.5 | ||||||

| 400 | 1000 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 17.5 | 26.0 | ||||||

1200 type clamping cylinder pressure contrast table

| Nominal diameter DN |

Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 28 | 700 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 | 7.5 | 8.0 | 12.0 | 12.0 | 18.0 | 19.0 | 27.0 | ||

| 32 | 800 | 3.0 | 3.5 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | 15.0 | 22.5 | ||||

| 36 | 900 | 3.0 | 5.0 | 5.5 | 7.0 | 7.5 | 11.0 | 12.0 | 18.0 | 19.0 | 27.0 | ||||

| 40 | 1000 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | 15.0 | 22.5 | ||||||

| 44 | 1100 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 17.0 | 25.5 | ||||||

| 48 | 1200 | 5.0 | 7.5 | 8.0 | 12.0 | 13.0 | 19.5 | 20.0 | 30.0 | ||||||

1400 type clamping cylinder pressure contrast table

| Nominal diameter DN |

Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 32 | 800 | 3.0 | 3.5 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | 15.0 | 22.5 | ||||

| 36 | 900 | 3.5 | 5.0 | 5.5 | 7.0 | 7.5 | 11.0 | 12.0 | 18.0 | 19.0 | 27.0 | ||||

| 40 | 1000 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | 15.0 | 22.5 | ||||||

| 44 | 1100 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 17.0 | 25.5 | ||||||

| 48 | 1200 | 5.0 | 7.5 | 8.0 | 12.0 | 13.0 | 19.5 | 20.0 | 30.0 | ||||||

| 56 | 1400 | 7.0 | 10.5 | 11.0 | 16.5 | 18.0 | 27.0 | ||||||||

1600 type clamping cylinder pressure contrast table

| Nominal diameter DN |

Nominal pressure of valve MPa/class | ||||||||||||||

| 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | |||||||||

| 150 | 300 | 400 | 600 | ||||||||||||

| Hydraulic system pressure (Pressure increasing) | |||||||||||||||

| in | mm | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS | PN | PS |

| 36 | 900 | 3.5 | 5.0 | 5.5 | 7.0 | 7.5 | 11.0 | 12.0 | 18.0 | 19.0 | 27.0 | ||||

| 40 | 1000 | 4.0 | 5.5 | 6.0 | 9.0 | 9.5 | 14.0 | 15.0 | 22.5 | ||||||

| 44 | 1100 | 4.5 | 6.5 | 7.0 | 10.5 | 11.0 | 16.5 | 17.0 | 25.5 | ||||||

| 48 | 1200 | 5.0 | 7.5 | 8.0 | 12.0 | 13.0 | 19.5 | 20.0 | 30.0 | ||||||

| 56 | 1400 | 7.0 | 10.5 | 11.0 | 16.5 | 18.0 | 27.0 | ||||||||

| 64 | 1600 | 9.0 | 13.5 | 14.5 | 21.5 | ||||||||||